DIY riveted sheet-metal magnet board

This giant riveted sheet-metal magnet board was the centerpiece of my office makeover that Sylvania sponsored. And now I’m going to show you how to make it. This is the first of a few tutorials from the Sylvania Blogger Makeover Challenge. Next week, I will show you how to make the studded mirror. (This post contains affiliate links. If you use these links to buy something, I may earn a small commission. You can read my full disclosure here.)

I originally planned to paint a sheet of plywood with magnetic paint, then cover it with some beautiful wallpaper. But then I read all the magnetic paint reviews at Lowes.com and decided otherwise. Apparently it takes at least six coats to achieve any measure of magnetism. I didn’t think a layer of wallpaper over weak magnetic paint was viable.

Then I saw Restoration Hardware’s Aviator Collection, which is based on World War II airplanes. As a WW II airplane buff, I fell in love with the furniture immediately — especially the Aviator Wing Desk and Spitfire Chair. Everything is clad in metal, leather, and hundreds of rivets — just like classic airplanes.

I already had an industrial theme going on with the galvanized steel table legs and galvanized planters and bins. Plus, I knew Lowe’s sold sheet metal, so this was the perfect solution for my office. All I needed was a rivet gun and my brother’s help.

How to make a riveted sheet-metal magnet board

SUPPLIES

TOOLS

INSTRUCTIONS

1. First, reinforce the plywood with a frame of 1x2s. The frame adds rigidity and provides adequate thickness to which the the picture hangers can anchor. Arrange the frame: Place the two side pieces first, 1½ inches from the edge, then place the top and bottom pieces (also 1½ inches from the edge) and the middle piece.

Notes: Troy did this step last, but he decided it would have been easier to do it first. He used 1x4s on the sides because it’s what I had on hand, but 1x2s are sufficient.

2. Apply wood glue to the back of one piece. Clamp it down. Hammer (or nail gun) one nail into each end of that piece. Repeat for all five pieces. Flip the entire frame/plywood over, then hammer in nails every few inches.

3. Lay the three panels of steel on top of the plywood, abutting each other. Measure the spacing of the holes and mark with a pencil. We placed the rivets ½ inch from the outside edge of each panel. Top and bottom: 8 rivets, about 3¼ inches apart. Sides: 11 rivets, about 3½ inches apart. Total for each panel: 34 rivets.

Tip: The pencil marks will not come off, so mark only where you will be drilling.

4. You will drill and rivet one corner of each panel to start with. So, drill a hole through the metal and plywood at one corner of the first panel. Skip to step 5. Then repeat for each corner at a time. Once each corner is riveted in place, repeat the process for the remaining two panels.

Tip: If you are using saw horses as a surface, clamp a scrap piece of wood underneath every hole that you drill. If you are working on the ground, simply place the scrap piece of wood underneath each time you drill. This will keep the plywood from blowing out and splintering on the back.

5. Move the scrap piece of wood out of the way. Insert a rivet into the hole you drilled. Hold a washer underneath the plywood as you use the rivet tool to fasten the rivet in place. The washer provides a solid surface to which the rivet can anchor. Return to step 4 and repeat for each corner.

Here’s a video of Troy fastening one rivet into a hole that he drilled in the sheet metal. Try doing that 102 times. Well, I did 4 of them, so that left 98 for Troy. The magnet board was our favorite part of the whole room, so it was worth it. Right, Troy?

6. Once all the corners are anchored down, you can drill the remaining holes on each side and fasten the rivets.

Tip: To save time and ensure your rivets line up, use your drywall T-square to mark the rivet placement on opposite sides.

8. Clean the grease off of the sheet metal with mineral spirits and a rag. Place the magnet board on a drop cloth. Spray two coats of Rust-Oleum Stops Rust crystal clear enamel, following the directions on the can. Let dry overnight.

Note: The grease protected the steel from rust, but it leaves black residue on your hands (and everything else it touches). That’s why we removed the grease and protected it with spray paint instead.

9. Flip the magnet board over. Drill holes and attach a D-ring hanger near the top of the 1×2 on each side. (Sorry, I forgot to take a picture of the D-ring hangers attached to the back of my magnet board — and it’s a bear to move.) The magnet board is heavy, so hang it on the wall from screws anchored into a stud or use molly bolts. Use a level and ruler to make sure your screws line up and it’s hung straight.

Share this story

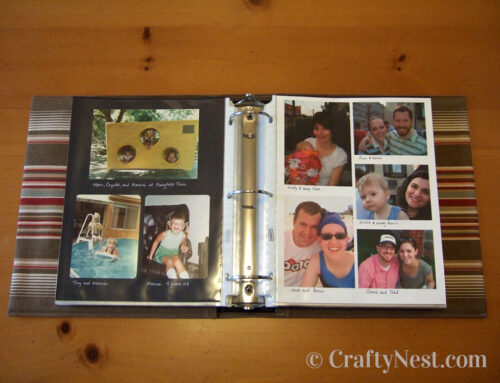

Reader Gallery

Made this project? Email your photo(s) to monica (at) craftynest (dot) com, and I’ll share your version here!

Leave A Comment